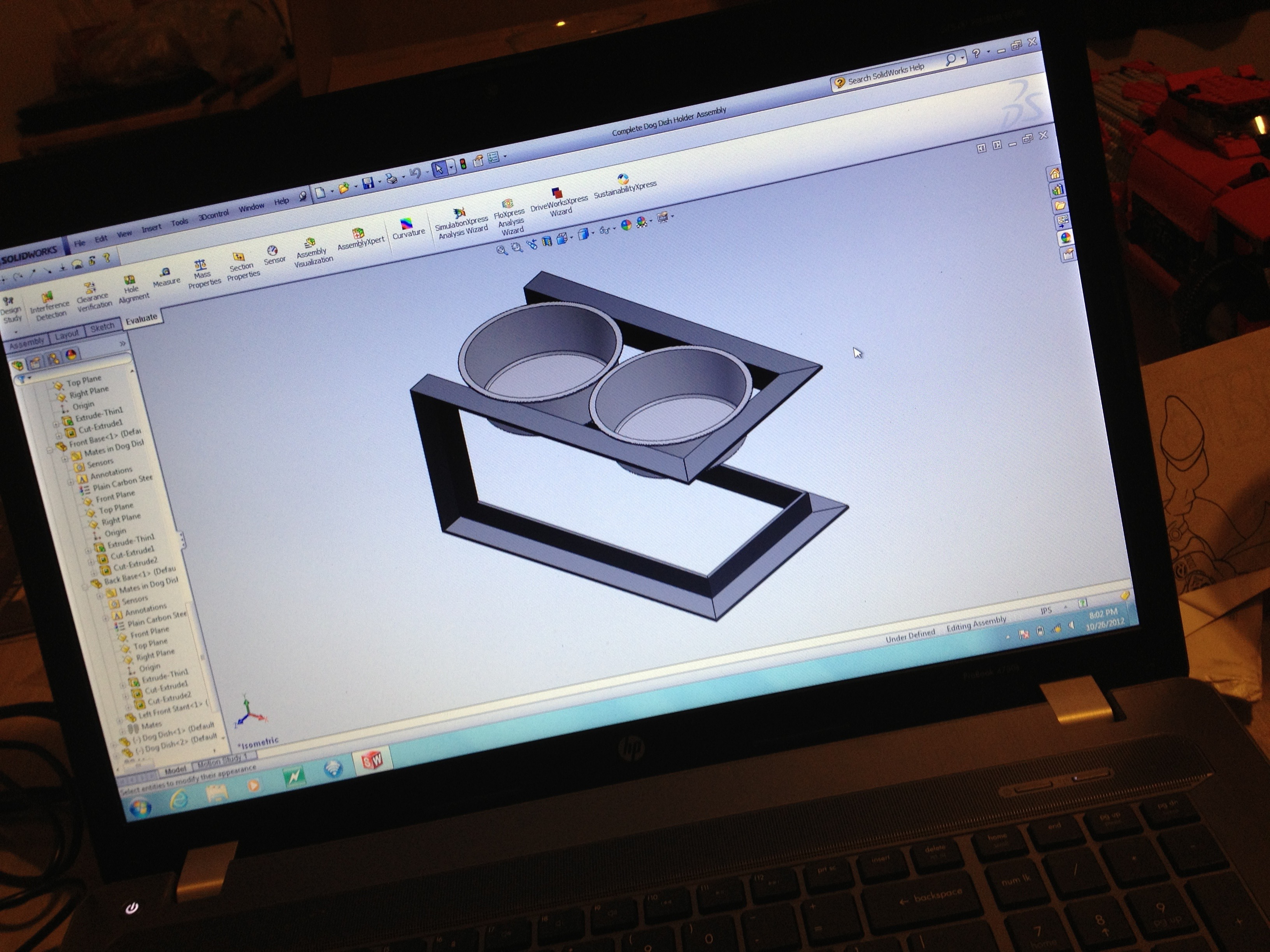

OBG Project – Raised Dog Dish Holder

My dog is not a large dog. At roughly 25 lbs and 13″ shoulder height, he’s not that far off the ground to really legitimately need a raised dog dish holder.

That was explained in detail to my wife before this project began. It didn’t matter. When it comes to our pooch, she is incredibly motherly (which I love about her) and did not want him straining his neck for all meals and water breaks.

Combine that with the fact that I had recently taken an intro welding course at our local hackerspace, she decided I needed a project that would test my mettle (mettle/metal… see what I did there?).

So one Phoenician fall morning back in 2012, I whipped up a concept in SolidWorks and ran to Home Depot for a few supplies.

Grabbed one 1″ x 1″ x 72″ (1/8″ Thick) length of angle steel and a can of spray paint, and made my way to the tool department to pick up a metal-cutting blade for my table saw.

HomeDepotGuy saw me wandering the aisles in search for the proper blade and asked me what he could help me with. After explaining the project, the tools I’d be using, and what I was looking for… he shut me out and tried selling me a brand-new $300+ chop saw because he claimed what I wanted didn’t exist, and cutting angle steel on a tablesaw was ‘impossible’ even if it did.

Feeling slightly dejected but mostly annoyed, I turned around to leave the department and walked right. Into. The. Blade. I. Needed.

Ha!

Now, I’m not going to say that it was super easy to miter-cut angle steel on an old table saw, but it was far from impossible. Had it all sliced up in an hour or so.

Since the day was still young, and there was nothing else going on that needed my attention, I grabbed all my bits & pieces, headed over to HeatSync Labs, and welded this puppy up for my puppy.

A few coats of paint later and it was finished:

Is it perfect? No, but it’s also not bad for my first ‘impossible’ welding project taken from concept to completion in under 24 hours.