Printrbot Simple Metal – I Live in the Future

I remember my first run-in with additive manufacturing. It was almost a decade ago while touring the facility at my summer internship during college. It was massive and had its own dedicated room, was expensive to own, and pricey to run. I don’t think I saw it being used the entire time I was there, but did notice almost every engineer’s desk had small 3D printed tchotchkes like hands and buckyballs.

I was amazed by this new technology (yes, I know it’s been around for longer than a decade). and marveled at the immense potential of taking the digital and at the push of a button, manifesting it into the physical realm. It seemed too futuristic… almost magical.

Fast forward a few years and 3D printers, while widely still in the unknown, had started to become more and more prevalent in industry. It was at this time that my wife and I had moved to Phoenix, I was in-between jobs, and tried to convince her to allow me to purchase one and start a small business prototyping for other small businesses. She’s a financial analyst, and after seeing that one of the machines would cost close to what we paid for our house (to be fair, we did get an extraordinary deal on the house), she did not bite.

In future employment, I did get to experience playing with industrial 3D printers and pushing development forward with them instead of being a distant observer. I have to say, holding a part in your hands that was only conceptual up until that moment is a powerful and exciting feeling.

And now that the technology has gone open-source and consumer, so many other people have been able to experience that same feeling. And they’ve done amazing things with it, from low-cost prosthetics to homes to functional firearms.

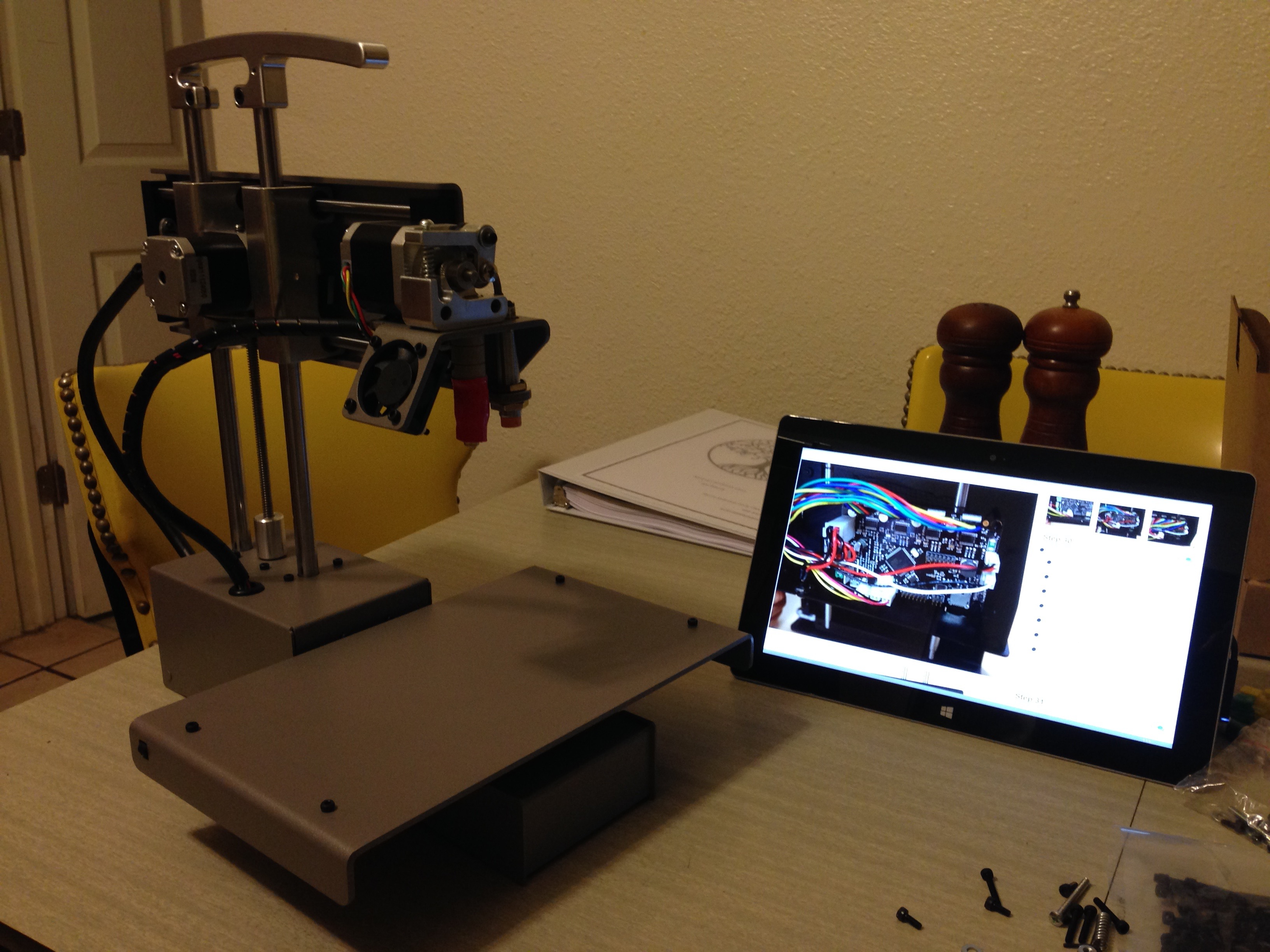

I too have recently gotten into home 3D printing, as earlier this year I ponied up and purchased a Printrbot Simple Metal!

Obviously I purchased the kit. I couldn’t pass up the chance and experience building one myself. Aside from the fun of that, I thought I’d get the most value by knowing how everything functions should I ever need to perform any maintenance on it.

The price was great too! at $539 and with free third-party software Cura, I almost couldn’t pass it up.

Printrbot’s documentation, forums, and customer support were fantastic in helping get everything put together, started up, and running. Once I had everything calibrated properly (which admittedly was a task all in itself), I was printing in no time at all.

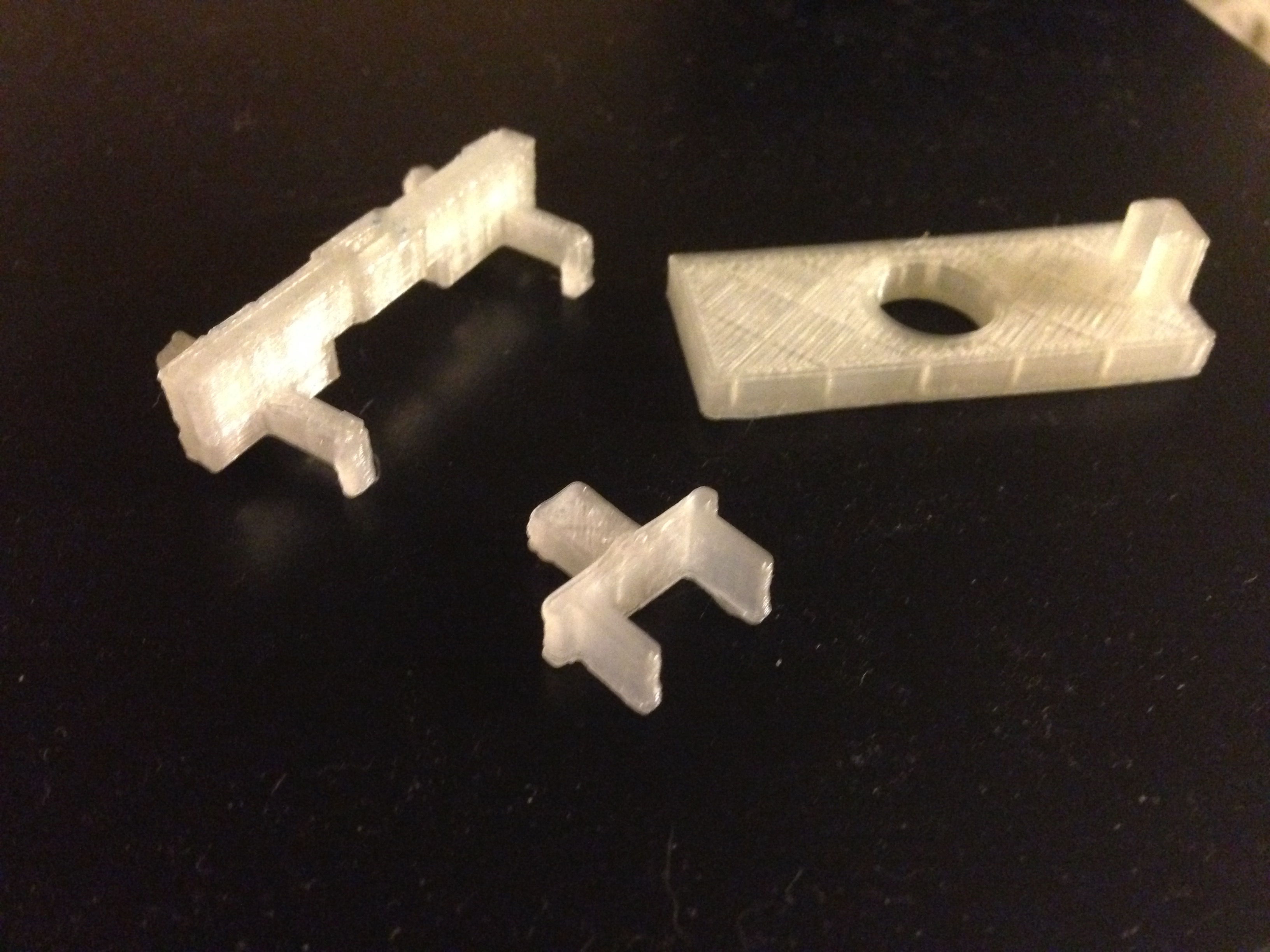

At 150 x 150 x 150 mm, the build area is smaller than others on the market (definitely won’t be fabricating any buildings right now), but the print resolution is great and the size helps me stay creative in my designs.

The material it accepts currently is any open-source 1.75mm PLA bioplastic, and I can upgrade the unit with a heated bed to handle ABS as well.

The future is here, and with my wife and I welcoming a baby girl into our lives recently, I am thrilled to have her grow up in an environment with limitless travel between her imagination and the physical realm. I’m going to need to start purchasing some of these spools:

1 Comment

Hello, I think your site might be having browser compatibility issues.

When I look at your blog in Safari, it looks fine but when opening in Internet Explorer, it has some overlapping.

I just wanted to give you a quick heads up! Other then that, fantastic blog!